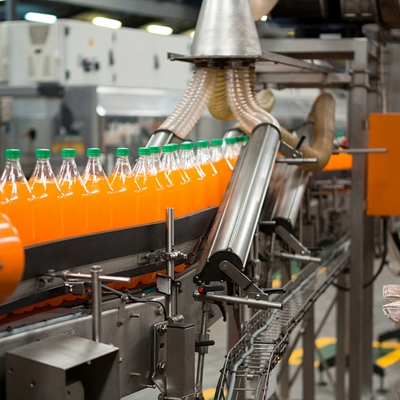

1. Integrated the functions of bottler washer, bottle filler and bottle capper.

2. The bottle filling equipment is mainly used for bottle packing of fruit juice, tea drink, etc..

Bottled purified water filling and minerals water filling are also applicable.

3. Hot drink filling machine is applicable for both plastic bottles and glass bottles.

1. Bottle-neck clamping device and bottle suspending design enable a stable filling under high-speed moving

conditions;

The need for filling different types of bottles can be realized easily by changing a few parts.

2. Stainless cap clips will not contact the area above the bottle's screw thread. And the equipped nozzles in clips

wash the interior of the bottle thoroughly.

3. The advanced micro negative-pressure filing technology used in this hot drink filling machine makes the filling

quickly, steady and accurate.

4. Fully enclosed beverage-holding tank; and temperature-control device and CIP washing interface are equipped.

5. The machine can meet all the technical requirements for hot-filling below 95¡æ.

6. RO washing device is adopted to wash bottle mouth before capping.

7. Magnetic torque is used for screw capping, which gives a free adjusting of cap screwing force and results in no

damage to caps.

8. Those parts need to directly contact with water and drinks are made of high quality stainless steel.

9. High safety is guaranteed by high quality electrical components like decelerator, the motor from Mitsubishi and

Omron.

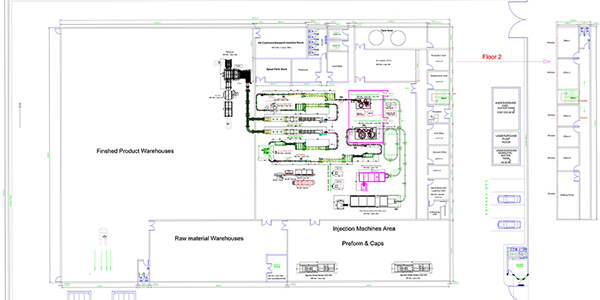

Complete bottle hot filling drinks production line

Complete bottle hot filling drinks production line

| Production Capacity(BPH) | Bottle Size(ml) | Total Power(KW) |

| 1500-36000 | 250-2000 | 4-22 |